A taste for the future

The typical image of the distillery industry, steeped in history and tradition, is not immediately associated with modern technology and digital innovation. Yet distilleries operate in a landscape of continual change, facing simultaneous challenges to meet enormous (and increasing) demand for product; choose which blends to create amidst ever-changing stock levels; and organise complicated production, maturation, storage and logistics processes. In such an environment the right technology is vitally important, with maturing inventory management solutions – stock control software specifically designed for the spirit distillation and management industry – playing an essential role. However, one of the main challenges facing distillers has often been overlooked, despite being central to many producers: long term planning. This gap is now being filled – a welcome development, given that 20 or even 30 years can be no time at all for a producer of fine whisky. While developing our own long term planning software solution, we in the DRAMS team spent a long time working with distillers in order to understand the different scenarios and information requirements involved in what is a hugely complex process. In this article we summarise the challenges associated with long-term planning, and explain technology’s role in helping to meet them.

Managing stock levels for production

For any organisation in the food and drink sector it is vital to have a clear and accurate view of what is in stock. The spirits industry couples this need with maturation periods of many years, and must also strike a balance between maximising sales today and maintaining stock levels for the decades to come. This challenge is complicated by commercial considerations relating to how much stock should be distilled at any one time. Having a five-year-old whisky as a flagship product is all very well, but that doesn’t mean it is sensible to allow the entire stock to be depleted – often it is necessary to allow some stock to age to ensure greater diversity in the future. The question of how much to distil is both complex and business critical – and must therefore be answered with consideration of data-informed long term strategy, rather than gut feel. The challenge here is not new of course, but in an increasingly competitive marketplace – and with both the variety and overall quantity of stock increasing so rapidly – it is critical that spirits producers are able to use planning tools that enable them to make long term forecasts and projections swiftly, smoothly and with the greatest possible degrees of accuracy.

Managing warehouse space and storage

Stock itself is an important consideration, but so too is where it will be housed. Warehouses represent huge costs for spirit producers, so it is essential to have sufficient storage space exactly when it will be required – but not sooner. This is a careful balancing act, since poor estimation either way has serious financial implications. Maintaining an accurate, real-time record of stock and planned stock feeds directly into investments in warehouse space and storage facilities, enabling distillers to understand how demand will direct future requirements – not only in terms of quantity and timing, but also type of stock, because an increase in ageing stock will of course need to mature for longer. Effective long term planning removes guesswork from this process, enabling distillers to understand exactly when – and increasingly where – they will need more capacity, resulting in informed decisions regarding investment in warehouses and other major capital projects.

Maximising profitability through effective blending

The choice of which spirits to combine into blended products and which to market and sell as standalone products is another significant challenge, since it is not simply about creating a top-quality product; it is also important to make sound decisions regarding where there will be stock surplus or a shortage of certain spirits. Similarly, if certain recipes require products with a finite supply – for example, a peated whisky last produced in 2003 – then distillers require an accurate picture of availability, projected price fluctuations and possible substitutions (an incredibly complex consideration; it’s not possible to simply swap one spirit for another) for the future that will maintain and grow revenue levels. Managers therefore have to produce a range of models incorporating their current stock, and sales forecasts over different periods of years. Such models can conceivably be produced manually, but the complexity here is such that this is both cumbersome and inefficient, and also worryingly error-prone (more on this later). It is therefore increasingly clear that distillers wishing to run smooth and scalable operations need to be able to automate these projections.

Informed sales and marketing strategy

The elements outlined so far show that effective long term planning enables distillers to obtain a complete picture regarding which spirits are likely to be available over the years ahead. This is vital because it provides marketing teams with the intelligence to stimulate demand in the required areas, enabling them to proactively drive sales. In other words, effective long term planning capabilities within a distillery management software solution aren’t only valuable in terms of the direct figures they produce – they enable personnel from across the business to gain new insights and to build more targeted strategies. There is also a related point here with regards to the sale of surplus stock: effective long term planning allows distillers to not only understand which stock they need, but also to make informed decisions relating to stock that isn’t planned for use in end products. Such stock can be sold without fear that doing so will prevent the meeting of demand further down the line.

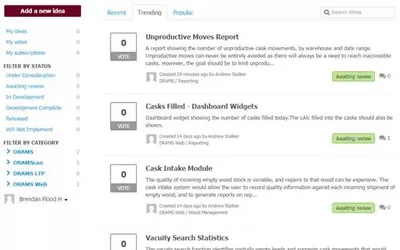

The risk of spreadsheets

Clearly this is a hugely complex area – one in which technology has a huge role to play. But what does that technological support actually look like? While it is true that there are few distilleries that still rely on paper calendars and calculators for forward planning, many do still use spreadsheets. For businesses that wish to grow and innovate, this is a hugely restrictive approach for two reasons. Firstly, standard productivity packages are simply not designed to deal with the specific – and highly complex, as detailed in this article – forward planning involved in spirits production. While an experienced practitioner can undoubtedly achieve highly productive results from a spreadsheet, less skilled staff may end up dangerously reliant on one or two individuals to make projections and manipulate figures for them. It is far safer, and more effective, to utilise technology that enables managers to harness available data to create reports and models at the touch of a button. Secondly, and arguably far more worryingly, spreadsheets introduce risk of formula errors and lost data, simply because they involve a degree of manual data entry. Scaled up to the level of a large organisation, the impact of such mistakes on future product lines grows too – indeed, reports suggest that reliance on spreadsheets literally costs businesses billions. The growth that the spirits industry has enjoyed has in turn increased the level of decision making. Large spirit producers make decisions regarding the purchase of hundreds of thousands of pounds of stock, directed in no small part by long term planning calculations. Making this type of decision based on figures in a spreadsheet at the mercy of human error feels like a disaster waiting to happen. There has to be a better way.

Centralising technology

If not in spreadsheets, then where? The case for dedicated long term planning technology appears clear. But where should this live? Given the importance of bulk stock management solutions, bringing these two technologies together appears a natural next step. Running bulk stock management and long term planning from a single software solution makes it possible to undertake valuable planning experiments: managers can adjust blend recipes or demand data in sales forecasts in order to analyse the impact; then apply decisions based on the results within the same application. But again, the most important aspect is one of data integrity and avoidance of risk. Utilising a single software tool for both processes avoids any risk involved in moving data from one application to another, ensuring a process of checks and balances to avoid the type of catastrophic error outlined in the previous section. In short: bringing bulk stock management and long term planning together serves as a data integrity failsafe, protecting the decisions being made now that will impact the business over the decades to come.

Looking backwards, moving forwards

Efficiency, flexibility, scalability and creative innovation – these are all essential qualities for spirits producers in today’s competitive marketplace. However, these qualities don’t displace the history and tradition integral to so many distilleries – if anything, they enhance them, by making it easier for decades-old practices and traditions to be maintained in a commercial world.